Product Center

-

Sodium chlorite high-purity chlorine dioxide gener

Reaction principle 5NaClO2+4HCl →4ClO2+5NaCl+2H2O Raw materials Sodium chlorite: (HG/T3250-2001 first grade industrial product, content ≥78%); Hydrochloric acid: (GB320-2006 industrial first grade product, concentration ≥31%) Composition of RC series chlorine dioxide generator 1. Feeding system 2.

-

chlorine dioxide generator(Chlorate)

Chemical Reaction principle: Heating NaClO3+2HCl → ClO2+1/2Cl2+H2O+NaCl Use raw materials : Sodium chlorate: (GB/T1618-2008 first grade industrial product, content ≥99%); Hydrochloric acid: (GB320-2006 industrial first grade product,concentration ≥31%) The composition of RJ series chlorine dioxide

-

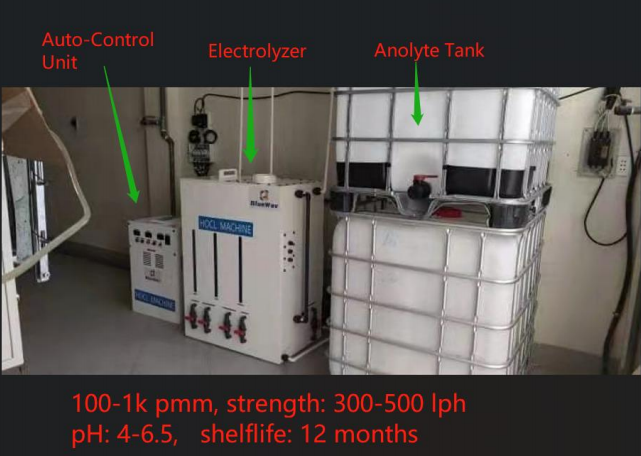

Anolyte HOCL Generator 500ppm 800ppm 1000ppm

Principle ofbrineelectrolysis Ourequipment electrolyzes a certain proportion of diluted brine (NaCl) in a special electrolytic module. In the advanced membrane, theAnode side produce outputHOCL/Anolyte/EOWElectrolyzed Oxidizing Water.No residue.Non-toxic, Non-Irritating,clean hocl solution. Applica

-

Medical Neutral Anolyte HOCl Generator

Principle ofbrineelectrolysis Ourequipment electrolyzes a certain proportion of diluted brine (NaCl) in a special electrolytic module. In the advanced membrane, theAnode side produce outputpureHOCL/Anolyte/EOWElectrolyzed Oxidizing WaterfortopMedical Gradeapplication. clean HOCL disinfectant. Appli

-

Food grade Anolyte HOCL Generator

Appication: Food/Seafood disinfection Beverage disinfection Baker disinfection Cold chain logistic Poultry/livestock disinfection Main features for HCIO acid water Generator, 1-ManualandFull AutomaticWorking, only 1 person required. 2-LCDtouch Screen operation,remote control by app on iPHONE/Androi