Electrochlorination systems have emerged as an indispensable technology in water treatment, showcasing remarkable versatility and functionality across multiple industrial domains. Their effectiveness is firmly rooted in a triad of critical attributes: operational excellence, cost-effectiveness, and environmental stewardship. By leveraging the electrolysis of saline solutions to generate on-site chlorine, these systems provide a reliable and secure means for disinfection and advanced water treatment processes. For instance, Chlory Company's sodium hypochlorite generators and seawater electro-chlorination systems exemplify the practical implementation of this innovative technology. This paper conducts a comprehensive and meticulous analysis of the five primary industrial applications of electrochlorination systems, with the objective of illuminating their profound impact on public health and ecological conservation.

1. Municipal Water Treatment: Guaranteeing Safe Potable Water for Communities

In the realm of municipal water treatment, electrochlorination systems assume a critical role of paramount importance. When consumers activate their domestic water faucets, they rightfully anticipate potable water that adheres to stringent safety standards for household use. Electrochlorination systems deployed within municipal water treatment infrastructure are indispensable in meeting these expectations. Through the electrolytic in-situ generation of chlorine, these systems execute a highly effective disinfection protocol, eliminating diverse pathogens, bacteria, and viruses from the water supply. This disinfection process serves as a cornerstone for maintaining public health and well-being. Empirical data from industry studies demonstrate that the integration of electrochlorination technology in water treatment facilities has resulted in a statistically significant decline in the incidence of waterborne diseases across adopting communities.

The in-situ chlorine generation capacity of electrochlorination systems constitutes a critical safety enhancement. Municipal water treatment entities can substantially reduce their dependence on the transportation and storage of hazardous chlorine gas, processes inherently associated with significant safety hazards. By mitigating these risks, electrochlorination systems elevate the operational safety standards of water treatment infrastructure, thereby instilling confidence in the public regarding the integrity of the water supply.

2. Effluent Treatment: Preserving Environmental Integrity

Industrial sectors are significant sources of effluent generation, necessitating stringent treatment protocols prior to the discharge of wastewater into the environment. Electrochlorination systems have emerged as a critical component in industrial wastewater treatment methodologies. Leveraging advanced electrochemical processes, these systems effectively degrade recalcitrant chemical compounds and inactivate pathogenic microorganisms within the effluent stream. Such treatment regimens are indispensable for mitigating environmental contamination and safeguarding aquatic biomes.

In manufacturing and chemical processing sectors, electrochlorination systems are instrumental in ensuring industrial effluent compliance with stringent environmental discharge regulations. Through advanced treatment mechanisms, these systems effectively remediate industrial wastewater, thereby preserving the ecological integrity of freshwater and marine ecosystems. By mitigating the impact of contaminants on aquatic habitats, electrochlorination systems safeguard biodiversity and support the sustainable management of water resources.

3. Oil and Gas: Boosting Operational Efficiency

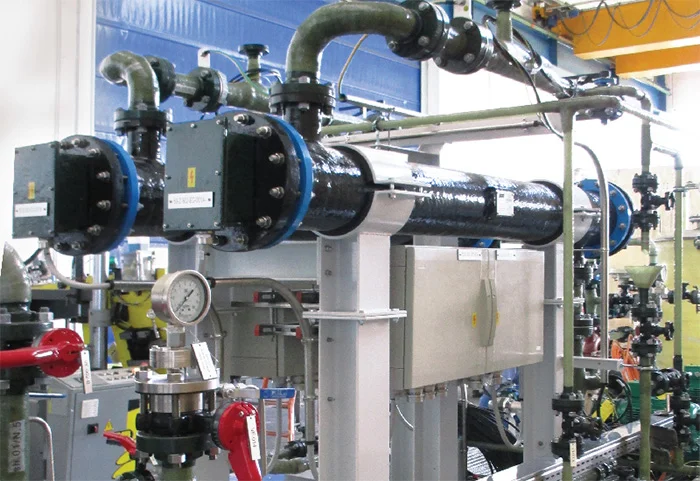

Offshore oil and gas platforms encounter unique challenges in maintaining water quality, primarily due to their exposure to the harsh marine environment. Electrochlorination systems have proven to be indispensable in addressing these challenges, particularly in preventing biofouling in seawater cooling equipment. Biofouling, the accumulation of microorganisms, plants, and animals on wetted surfaces, can significantly impede the efficiency of cooling systems and lead to equipment failures.

Electrochlorination systems combat biofouling by continuously generating chlorine, which inhibits the growth and attachment of fouling organisms. Their reliability in the harsh marine environment, characterized by high salinity, fluctuating temperatures, and strong currents, makes them a preferred choice for offshore operations. The ability of these systems to operate continuously without frequent maintenance ensures the smooth and efficient operation of vital equipment on oil and gas platforms, thereby enhancing overall operational efficiency and reducing downtime.

4. Power Generation: Ensuring Uninterrupted Power Supply

In power generation facilities, substantial volumes of water are required for cooling operations, and the integrity of this cooling water supply is a critical determinant of plant operational efficiency. Electrochlorination systems are strategically deployed to purify the cooling water, effectively inhibiting the proliferation of algal blooms and other microbiological contaminants. This intervention mitigates the risk of fouling in cooling equipment, thereby safeguarding against performance degradation and ensuring optimal heat transfer efficiency.

Electrochlorination systems serve as an indispensable safeguard for power plant cooling water systems, ensuring water quality and system integrity through advanced electrochemical treatment processes. This methodical approach to water treatment is essential for optimizing the performance of critical cooling infrastructure, thereby enhancing the durability and longevity of associated equipment. By effectively controlling corrosion, biofouling, and scaling phenomena, electrochlorination systems substantially decrease equipment replacement requirements and maintenance interventions. In the power generation industry, where operational continuity is of utmost importance, the implementation of electrochlorination systems is critical for maintaining grid stability and reliability by ensuring uninterrupted power supply.

5. Marine Industry: Facilitating Safe and Sustainable Operations

In maritime vessels, coastal settlements, and remote locales with restricted access to freshwater resources, desalination plants serve as indispensable infrastructure for the conversion of seawater into potable water. Electrochlorination systems are integral to the desalination process, acting as a safeguard against the accumulation of biofilms and fouling agents on reverse osmosis membranes. Through the controlled generation of hypochlorous acid, these systems maintain membrane integrity and operational efficiency, thereby enabling the consistent production of potable water that meets the stringent quality standards required for human consumption and industrial use.

of hypochlorous acid, these systems maintain membrane integrity and operational efficiency, thereby enabling the consistent production of potable water that meets the stringent quality standards required for human consumption and industrial use.

In addition to desalination, marine vessels rely on extensive cooling systems to maintain the functionality of their engines and other equipment. Electrochlorination systems are employed to control microbial growth and prevent biofouling in these cooling systems. By doing so, they ensure the efficient operation of the vessels, reduce maintenance requirements, and enhance the overall safety and sustainability of marine operations.

At Pristine Water, we take pride in our comprehensive portfolio of electrochlorination systems, meticulously designed to meet the diverse and specific needs of various industries. We recognize that each industry presents unique challenges and requirements, and our team of experts is dedicated to providing tailored solutions. Through in-depth consultations and assessments, we work closely with our clients to identify their precise needs and recommend the most suitable electrochlorination system for their operations. Chlory has been working hard on the research and development of the electrochlorination system. Our goal is to ensure optimal performance, cost-efficiency, and long-term reliability, enabling our clients to achieve their water treatment objectives effectively.