I. Application background and demand

The condenser cooling water system of coastal thermal power plants generally adopts seawater direct cooling, but the seawater contains a large number of marine larvae, algae and halophilic bacteria. These organisms are easy to attach to the surface of pipes, condensers and heat exchangers, resulting in a reduction in the flow section of the flow channel and an increase in the head loss of the circulating water system, which in turn leads to a decrease in equipment operating efficiency and the risk of biological corrosion. Traditional manual cleaning methods require shutdown operations and are less economical, so chemical means are needed to inhibit biological contamination. Electrolytic seawater sodium hypochlorite generators have become a key technology to solve this problem by preparing high-efficiency bactericides on site. The application of Bluewav's electrolytic seawater sodium hypochlorite generator in actual production has successfully realized this demand.

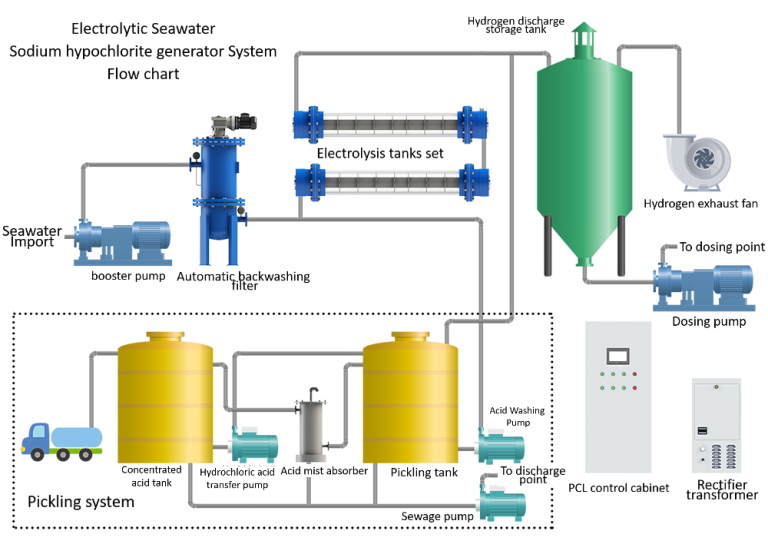

II. Technical principles and system composition

Electrolysis reaction mechanism

The following reaction occurs when seawater (containing sodium chloride) is electrolyzed:

The generated sodium hypochlorite (NaClO) destroys the microbial cell structure through strong oxidizing properties to achieve bactericidal and algae inhibition.

Core equipment composition

Electrolytic cell: titanium-based anode and corrosion-resistant isolation material are used, and the electrode surface is treated with nano-coating, with a service life of 5-7 years;

Proportioning system: seawater or industrial salt is prepared into 3%-5% dilute brine, and the concentration is accurately controlled by PLC;

Heat dissipation and control system: integrated silicon rectifier control cabinet and cooling device to ensure stable temperature during the electrolysis process.

III. Application advantage analysis

Safety improvement

On-site preparation of sodium hypochlorite (concentration 6000-8000 ppm) avoids the risk of liquid chlorine storage and transportation, and is especially suitable for sensitive scenarios such as coastal power plants.

Outstanding bactericidal efficiency

Sodium hypochlorite has a broad-spectrum killing effect on marine larvae, spores, viruses, etc., and can maintain the long-term cleanliness of the circulating water system. A 600,000-kilowatt unit successfully inhibited the biological attachment of the condenser and reduced the risk of pipeline corrosion by continuously adding sodium hypochlorite (annual consumption of about 5,400 tons).

Economic and environmental protection

Compared with traditional liquid chlorine addition, the raw material cost of the electrolysis method is reduced by 30%–50%, and the decomposition products of sodium hypochlorite are harmless salts, which meet environmental protection requirements.

IV. Application practice and optimization direction

Improvement of water quality adaptability

For high pH circulating water (pH>8.5), neutralizing agents need to be added to improve the sterilization efficiency and reduce the oxidative corrosion of sodium hypochlorite on the pipeline.

Operation parameter optimization

Control the electrolysis current density ≤20 A/dm² and the electrolysis temperature ≤40℃ to extend the electrode life ;

Regularly clean the calcium and magnesium scale in the electrolytic cell, the water softener needs to be backwashed weekly and the resin filter material needs to be replaced every three years .

V. Conclusion

The electrolytic seawater sodium hypochlorite generator effectively solves the problem of biological pollution in the cooling system of coastal power plants through precise preparation, intelligent addition and efficient sterilization. Its safety, economy and environmental friendliness have been verified in many large thermal power plants in China (such as Aksu, Xinjiang, Zhenyuan, Guizhou, etc.). Bluewav has been committed to the production and research and development of sodium hypochlorite generators for electrolyzing seawater. With the continuous upgrading of electrode materials, intelligent control and other technologies, this equipment will play a more important role in the field of power plant water treatment.