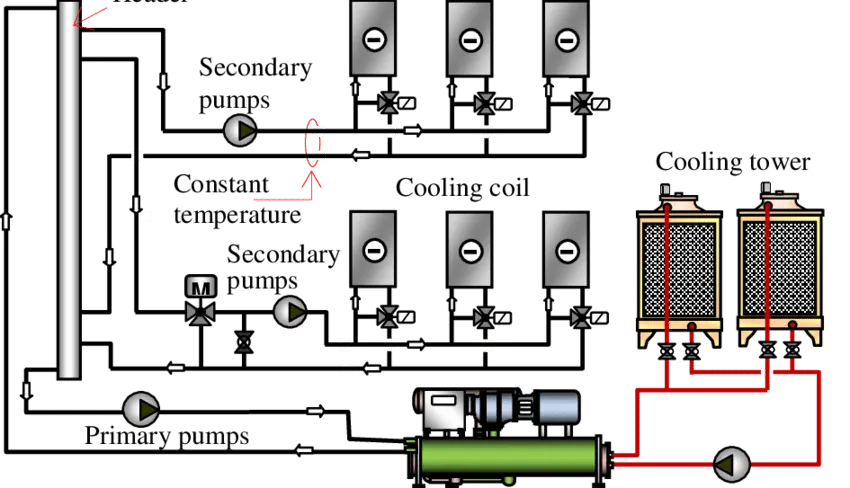

In the field of energy management and environmental control for modern buildings, water-cooled central air conditioning systems have become the top choice for large commercial buildings, hospitals, data centers, and other facilities due to their high energy efficiency and flexible adjustment capabilities. However, during the long-term operation of water-cooled systems, cooling water is prone to microbial growth, scaling, and pipeline corrosion, which seriously affect the performance and service life of the equipment. Sodium hypochlorite generators produced by Chlory Company, characterized by high efficiency, safety, and environmental friendliness, have gradually become a key technology for water quality management in water-cooled central air conditioning systems.

I. Working Principles and Characteristics of Sodium Hypochlorite Generators

Sodium hypochlorite generators operate based on electrochemical principles, producing sodium hypochlorite (NaClO) solution by electrolyzing sodium chloride (NaCl) solution. During the electrolysis process, an oxidation reaction occurs at the anode, where chloride ions (Cl⁻) lose electrons to form chlorine gas (Cl₂). At the cathode, a reduction reaction takes place, where water (H₂O) gains electrons to produce hydrogen gas (H₂) and hydroxide ions (OH⁻). Chlorine gas then reacts with hydroxide ions to ultimately form sodium hypochlorite. The reaction equations are as follows:

Anode: 2Cl⁻ - 2e⁻ → Cl₂

Cathode: 2H₂O + 2e⁻ → H₂ + 2OH⁻

Total reaction: Cl₂ + 2NaOH → NaClO + NaCl + H₂O

The generated sodium hypochlorite is a strong oxidant. Its main component, hypochlorite ion (ClO⁻), has high - efficiency bactericidal and algicidal capabilities, capable of rapidly destroying the cell structure of microorganisms and inhibiting algae growth. Meanwhile, sodium hypochlorite can hydrolyze in water to produce nascent oxygen, which has certain corrosion inhibition and scale prevention effects, effectively maintaining the stability of the water quality in the water-cooled system. Compared with traditional chemical agents (such as liquid chlorine and chlorine dioxide), sodium hypochlorite generators produce the solution on-site and use it as it is produced, eliminating the need for storing and transporting hazardous chemicals, thus greatly reducing safety risks and management costs.

II. Core Advantages of Sodium Hypochlorite Generators in Water-Cooled Central Air Conditioning Systems

(I) High-Efficiency Bactericidal and Algicidal Properties to Ensure Stable System Operation

During the cooling water circulation of water-cooled central air conditioning systems, suitable temperature, humidity, and lighting conditions provide an ideal living environment for microorganisms such as bacteria, algae, and Legionella. The massive reproduction of microorganisms not only forms biological slime, blocking pipelines and heat exchangers and reducing heat exchange efficiency, but may also pose health risks such as Legionnaires' disease. The sodium hypochlorite solution produced by sodium hypochlorite generators can quickly kill various microorganisms, with a bactericidal efficiency several times higher than that of ordinary disinfectants. Research shows that at an appropriate dosing concentration (usually 1 - 3mg/L), the killing rate of sodium hypochlorite against Legionella can reach over 99%, effectively ensuring the safe operation of the system.

(II) Economic and Environmentally Friendly, Reducing Operating Costs

Traditional water treatment methods often use chemical agents such as liquid chlorine and chlorine dioxide. These agents pose high safety risks during storage and transportation and require regular procurement, resulting in fluctuating costs. Sodium hypochlorite generators use common salt as raw material, which is widely available and has a stable price. The operating costs of the equipment only include the consumption of salt and a small amount of electricity. According to actual case calculations, using sodium hypochlorite generators for water treatment can reduce the annual operating costs of water-cooled central air conditioning systems by 20% - 30%. In addition, sodium hypochlorite decomposes without harmful residues and does not cause secondary pollution to the environment, in line with national green building and environmental protection policy requirements.

(III) Automated Control, Improving Management Efficiency

Modern sodium hypochlorite generators are equipped with intelligent control systems that can automatically adjust the production and dosing amount of sodium hypochlorite according to the water quality parameters of the water-cooled system (such as residual chlorine content, pH value, turbidity, etc.). By linking with the central air conditioning control system, the equipment can monitor the system operation status in real-time and achieve unattended automated operation. Managers can view equipment operation data and fault alarm information at any time through the remote monitoring platform, greatly improving the convenience and efficiency of system management.

III. Key Points for the Application of Sodium Hypochlorite Generators in Water-Cooled Central Air Conditioning Systems

(I) Rational Selection and Installation

Select an appropriate specification of sodium hypochlorite generator according to the circulating water volume, water quality conditions, and treatment requirements of the water-cooled central air conditioning system. The effective chlorine production of the equipment should meet the maximum treatment requirements of the system and reserve a certain margin. During installation, ensure that the connection position between the generator and the cooling water circulation pipeline is reasonable to avoid affecting the mixing uniformity and disinfection effect of sodium hypochlorite due to factors such as water flow velocity and pipeline layout. At the same time, the equipment should be installed in a well-ventilated and dry place for easy daily maintenance and repair.

(II) Precise Control of Dosing Amount

The dosing amount of sodium hypochlorite directly affects the disinfection effect and water quality safety. Insufficient dosing cannot effectively kill microorganisms, while excessive dosing may lead to high residual chlorine in the water, accelerating pipeline corrosion. In practical applications, adjust the dosing amount dynamically according to the water quality monitoring data of the system. Generally, increase the dosing amount appropriately for shock treatment at the initial stage of system operation. After the water quality stabilizes, control the residual chlorine content within the range of 0.5 - 1.0mg/L. In addition, regularly detect the pH value of the water. When the pH value is too high (>8.5), the bactericidal activity of sodium hypochlorite will decrease, and acidic regulators can be added for adjustment.

(III) Regular Maintenance and Upkeep

The electrolytic cell of the sodium hypochlorite generator is a core component. After long-term operation, deposits such as calcium and magnesium scale and metal oxides will form on the surface of the electrodes, affecting the electrolysis efficiency. Therefore, regularly carry out acid cleaning and descaling of the electrolytic cell (usually once every 3 - 6 months), and check the electrode wear condition at the same time, replacing aging electrodes in a timely manner. In addition, regularly inspect the operation status of components such as the salt tank, metering pump, and control system to ensure the stable and reliable operation of the equipment.

IV. Application Case Analysis

A commercial complex in London, UK: In the past, traditional chlorination methods were used for water treatment, resulting in frequent fluctuations in residual chlorine concentration and pipeline corrosion. After installing a new type of sodium hypochlorite generator in 2021, the detection rate of Legionella decreased by 85%, the corrosion rate of the entire system slowed down by 50%, and 250,000 pounds could be saved annually on chemical procurement and equipment maintenance costs. Moreover, automated control reduced manual operation by 30%.

A convention center in Chicago, USAwas also troubled by water quality management issues of its water-cooled central air conditioning system. The previous chlorination system was extremely dangerous, with a high risk of liquid chlorine leakage, and the chlorine consumption was high, making it difficult to reduce costs. After replacing it with an intelligent sodium hypochlorite generator in 2020, remarkable results were achieved: Legionella contamination incidents decreased by 90%, the scaling rate of condensers slowed down by 60%, and 400,000 US dollars could be saved annually on water treatment costs. Coupled with the Internet of Things monitoring system, the equipment can be adjusted remotely from the office. Previously, inspections were required three times a week, but now only once a month is needed, making management much easier.

A large hospital in Tokyo, Japanonce experienced infection incidents due to poor water quality management of its water-cooled central air conditioning system. After using an integrated sodium hypochlorite generation device in 2019, the reproduction of microorganisms was effectively controlled. The positive sample rate of Legionella plummeted from 15% to 1.5%, the heat exchange efficiency increased by 40%, and more than 30 million yen could be saved annually on energy consumption costs. The equipment downtime due to failures also decreased by 60%, ensuring the stable operation of the hospital.

Chlory Company has been committed to the research, development, and production of sodium hypochlorite generators. With the continuous development of building energy-saving and intelligent technologies, sodium hypochlorite generators will be more widely used in water-cooled central air conditioning systems due to their high efficiency, safety, and economic characteristics. Through rational selection, precise control, and scientific maintenance, sodium hypochlorite generators can not only ensure the stable operation of water-cooled systems but also bring significant economic benefits and environmental benefits to users, contributing to the development of the construction industry towards a green, low-carbon, and sustainable direction.