In cold chain transportation projects, how to ensure that food remains fresh after a long journey is a crucial issue. The emergence of hypochlorous acid generators has brought new solutions to cold chain transportation preservation, which can effectively extend the shelf life of food and prevent food from spoiling during transportation.

Traditional cold chain transportation preservation technologies, such as low-temperature preservation, mainly inhibit the reproduction of microorganisms and slow down the respiration of fruits and vegetables through low temperatures. However, it has problems such as slow cooling speed and uneven cooling temperature, a high damage rate to food, and no other effects except cooling. Chemical preservation uses chemical preservatives such as disinfectants to inhibit microbial growth and food physiological activities. Although it can extend the shelf life to a certain extent, there may be chemical residues that affect food safety. Biological preservation uses natural substances with antibacterial or bactericidal activity to prepare solutions for the preservation of fresh food, but the preservation effect is limited and the scope of application is narrow.

The preservation principle and advantages of hypochlorous acid

Hypochlorous acid can preserve food in the following ways. First, it can inhibit the production of ethylene, which is a gas that promotes the maturation and aging of food. Hypochlorous acid can effectively control the release of ethylene from food and delay its maturation process, thereby extending the freshness and shelf life of food. Second, hypochlorous acid has a strong bactericidal ability and can kill pathogenic microorganisms on the surface or inside of food. The growth of microorganisms is one of the important reasons for food spoilage. Hypochlorous acid kills these microorganisms and reduces their damage to food, thereby achieving the purpose of preservation. Third, hypochlorous acid can also regulate the respiratory metabolism of food after harvesting, reduce its respiratory intensity, reduce the consumption of nutrients, and further maintain the quality of food.

Hypochlorous acid has many significant advantages in terms of preservation. It has broad-spectrum bactericidal properties and can effectively kill a variety of pathogenic microorganisms including bacteria, fungi, viruses, etc., greatly reducing the risk of food infection. Moreover, hypochlorous acid preserves food without leaving any residue. It can be converted back into water after use and will not leave any harmful substances on the surface of food, thus ensuring food safety. At the same time, hypochlorous acid is non-toxic, harmless to the human body and the environment, and is safer and more reliable to use. In addition, hypochlorous acid has a rapid bactericidal effect and can take effect in a short period of time, providing timely protection for food.

Application of hypochlorous acid generator in cold chain transportation

During cold chain transportation, the hypochlorous acid generator can produce hypochlorous acid solution on-site and use it immediately, which not only ensures the effect but also saves overall costs. The hypochlorous acid generator uses salt as raw material. The hypochlorous acid solution produced does not contain any hazardous chemicals, is safer, and the raw materials are easier to purchase, transport and store, and the cost is lower. It is very suitable for food preservation during cold chain transportation.

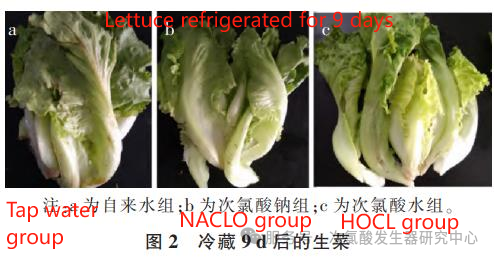

In actual operation, different treatment methods can be used for different types of food. For example, for fruits and vegetables, they are first pretreated before preservation, including precooling, sorting and washing. Precooling slows down the respiration of fruits and vegetables and prolongs the physiological cycle of fruits and vegetables; those with complete appearance, full development, freshness and cleanness are sorted out for washing. The purpose of washing is to remove dirt and a small amount of pesticide residues on the surface of fruits and vegetables. After pretreatment, hypochlorous acid (slightly acidic electrolyzed water) is used for treatment. Depending on the type of fruits and vegetables, soaking or spraying treatment methods are selected for 2-10 minutes. It can sterilize and preserve. After treatment, it is air-dried, packaged, and enters the cold chain transportation link. For other foods such as meat and aquatic products, hypochlorous acid solution can also be used for sterilization and preservation in an appropriate way, effectively extending their shelf life in cold chain transportation, ensuring that they still maintain good quality when they reach consumers.

In areas such as fresh food and pharmaceutical cold chain that have extremely high requirements for preservation, Chlory has innovatively launched an integrated solution of hypochlorous acid generator + cold chain transportation, redefining full-process sterile preservation with cutting-edge technology!

Efficient sterilization, worry-free throughout the process

Chlory hypochlorous acid generator instantly generates high-purity hypochlorous acid (HCLO) with a sterilization rate of up to 99.9%. It can be seamlessly integrated into refrigerated trucks and cold storage environments, and continuously releases safe and residue-free sterilization factors under low temperature conditions, effectively inhibiting the growth of microorganisms such as Escherichia coli and Salmonella, extending the shelf life of food, and ensuring the absolute safety of medicines and fresh food during transportation.

Low temperature adaptation, precise preservation

Traditional preservation methods are prone to failure in the cold chain, but Chlory hypochlorous acid technology can work stably in an environment of -25℃~15℃, without freezing or corroding equipment. It is perfectly adapted to various cold chain scenarios and locks in freshness from source to terminal.

Green and safe, compliant and environmentally friendly

After decomposition, hypochlorous acid turns into only water and trace salt, without any toxic byproducts. It complies with FDA and EPA international certifications, eliminates the health risks of traditional chemical preservatives, and helps companies pass strict certifications such as HACCP and GMP.

Smart IoT, worry-free and cost-saving

It supports real-time concentration monitoring and remote control, dynamically adjusts sterilization intensity, reduces manual intervention, reduces cold chain loss rate by more than 30%, and uses technology to save every penny for the enterprise.

Chlory——Let every cold chain become the guardian of quality!

Consult now to unlock your exclusive preservation solution!

+86 157 8668 8998