As a special public place, the safety of the water supply system of the hospital is directly related to the health of patients, medical staff and visitors. Pathogenic microorganisms that may breed in cold water pipes, such as Legionella and Pseudomonas aeruginosa, pose a serious threat to patients with low immunity. Hypochlorous acid (HClO), as an efficient and safe disinfectant, is gradually becoming the preferred solution for disinfection of cold water pipes in hospitals. This article will explore the application of hypochlorous acid in the disinfection of cold water pipes in hospitals, and focus on the unique advantages of Chlory5 hypochlorous acid generator in this field.

Disinfection mechanism of hypochlorous acid

Hypochlorous acid is a weak acid with a small molecular weight and no charge. It can easily penetrate the cell wall and cell membrane of microorganisms and exert its bactericidal effect through the following ways:

- Oxidation of proteins and lipids on bacterial cell walls and membranes

- Destruction of enzyme systems and DNA/RNA structures in cells

- Interference with cell energy metabolism and material transport

- Compared with traditional chlorine disinfectants, hypochlorous acid has a higher bactericidal efficiency. At the same concentration, its bactericidal rate is 80-120 times that of sodium hypochlorite (NaClO).

- Special needs for disinfection of cold water pipes in hospitals

Hospital cold water pipe systems face unique microbial control challenges:

- Legionella risk: areas with water temperatures of 25-45°C are prone to Legionella growth, which may lead to fatal Legionnaires' disease

- Biofilm problem: Long-term biofilms formed in pipes provide shelter for pathogens

- Resistant strains: Strains resistant to conventional disinfectants may appear in hospital environments

- Water quality safety: Disinfection byproducts may pose additional risks to immunocompromised patients

- System complexity: Large hospitals have complex pipe systems with dead water ends and low flow rate areas

Technical advantages of Chlory Co. hypochlorous acid generators

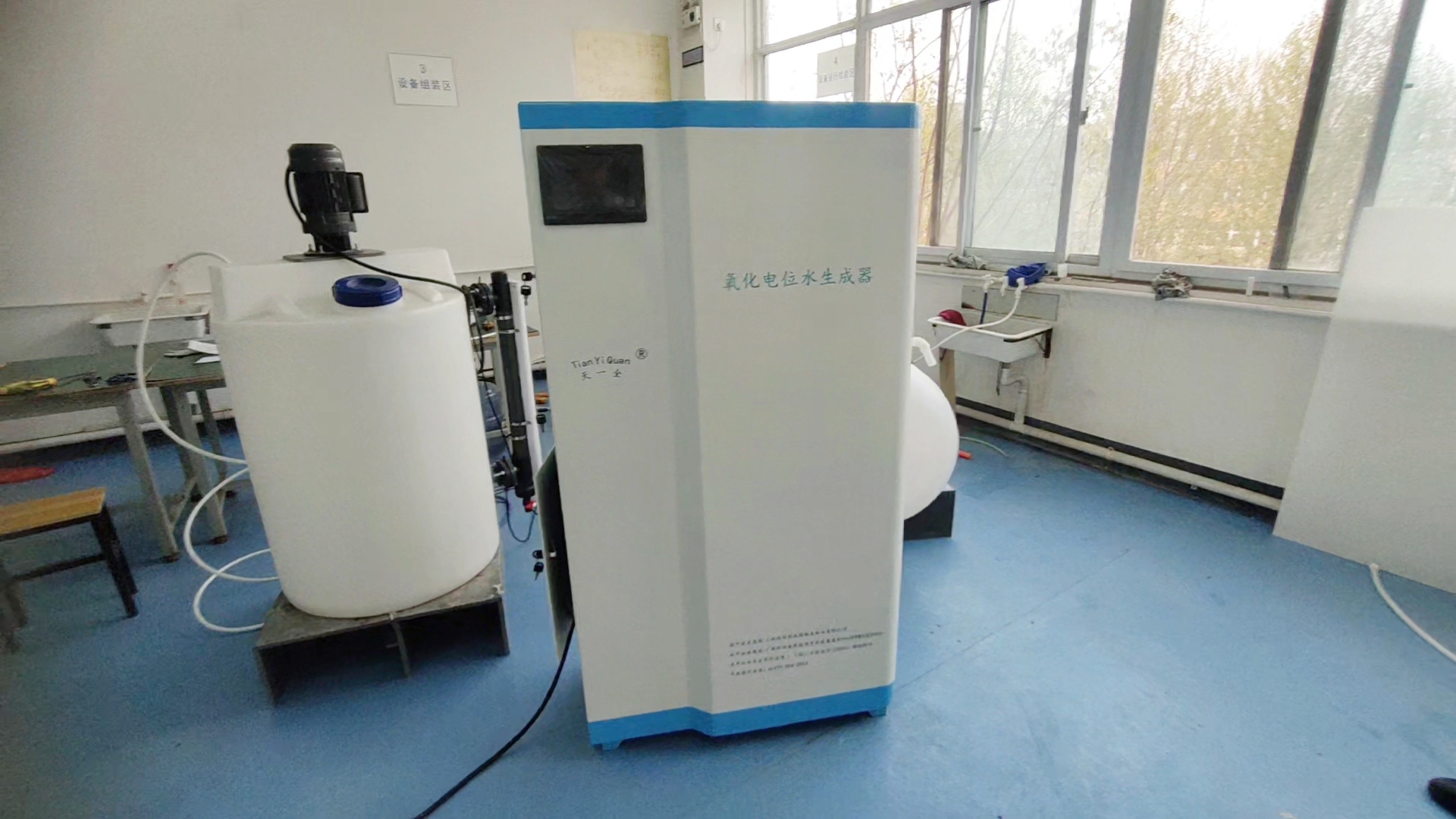

Chlory hypochlorous acid generators use advanced electrolysis technology to directly generate high-purity hypochlorous acid solution from salt and water, with the following significant advantages:

- On-site preparation, fresh and efficient: produce hypochlorous acid solution on demand, Avoid storage and transportation risks and ensure the activity of disinfectants

- Precise concentration control: The intelligent control system can accurately adjust the concentration of hypochlorous acid (0.1-5ppm) to meet different needs

- Broad-spectrum and efficient sterilization: It has excellent killing effects on bacteria, viruses, fungi and spores, especially effective against Legionella

- Safe and environmentally friendly: There are few disinfection by-products, no irritating odor, and it decomposes into water and trace salts, which is environmentally friendly

- Anti-biofilm ability: Small molecule hypochlorous acid can penetrate biofilms and remove microbial communities in pipelines

- Intelligent monitoring and feedback: Integrated water quality monitoring system, real-time adjustment of dosage, to ensure stable disinfection effect

Hospital cold water pipeline disinfection application solution

- Hospital cold water pipeline disinfection system based on Chlory hypochlorous acid generator usually includes the following components:

- Central preparation system: Select a generator with appropriate production capacity according to the scale of the hospital

- Multi-point dosing device: set dosing points at key nodes of main pipelines and branch pipelines

- Online monitoring network: real-time monitoring of residual chlorine concentration, pH value and oxidation-reduction potential (ORP)

- Automatic control system: automatically adjust the dosage according to water consumption and pollution load

- Periodic impact disinfection program: set up regular high-concentration flushing mode for biofilm problems

Implementation effect and case verification

Many medical institutions have reported significant results after using hypochlorous acid generators to disinfect cold water pipelines:

- Microbial control: the detection rate of pathogens such as Legionella is reduced by more than 95%

- Biofilm inhibition: the formation of biofilm on the inner surface of the pipeline is reduced by 80-90%

- Water quality improvement: odor and color problems are significantly improved

- Maintenance cost: compared with traditional disinfection methods, maintenance cost Reduce by 30-40%

- Safety record: No health complaints related to disinfectants were reported during use

Economic and sustainability analysis

Chlory hypochlorous acid generators have shown good economic and environmental advantages in hospital applications:

- Low operating costs: only salt, water and electricity are required, and the raw material cost is low

- Long equipment life: The core electrolyzer has a design life of more than 10,000 hours

- Energy-saving design: Compared with traditional chlorine disinfection systems, energy consumption is reduced by 25-35%

- Reduced chemical transportation: Avoid the risk of transporting and storing large amounts of disinfectants

- Meet green hospital standards: Support hospitals to achieve environmentally friendly operation goals

Conclusion

As a new generation of disinfectants, hypochlorous acid has shown excellent performance and safety in the disinfection of hospital cold water pipes. With its advanced technical features, Chlory hypochlorous acid generators provide medical institutions with an efficient, economical and environmentally friendly pipe disinfection solution. Through precise control, broad-spectrum bactericidal and excellent anti-biofilm ability, the system can effectively reduce the microbial risk of hospital water systems, especially suitable for medical environments with strict infection control requirements. As hospitals pay more attention to water safety, hypochlorous acid disinfection technology is expected to become a standard configuration for water system management in medical buildings.

Contact:

WA+86 157 8668 8998