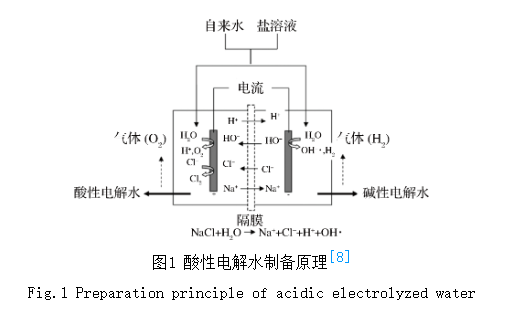

Acidic electrolyzed water is prepared by electrolysis with a diaphragm device, and slightly acidic electrolyzed water and neutral electrolyzed water are obtained by electrolysis without a diaphragm device. The electrolyzed water produced by the two devices has the ability to sterilize and preserve aquatic products. Among them, in the electrolytic cell, electrochemical reactions occur at the positive and negative electrodes. 2Cl-→Cl2+2e-; Cl2+H2O→HCl+HClO; 2H2O→4H++O2+4e-, acidic electrolyzed water is obtained at the anode; 2H2O+2e-→ H2+2OH-, alkaline electrolyzed water is obtained at the cathode, as shown in Figure 1.

Zhao Aijing et al. found that the concentrations of Na+ and Cl- in the electrolyte are much higher than the concentrations of H+ and OH- produced by weak electrolysis of water. Under the action of the electric field, Cl2 is generated at the anode, which then forms HCl and HClO. This causes the H+ concentration to be higher than the OH- concentration near the anode, generating acidic electrolyzed water at the anode. Currently, most studies on the bactericidal mechanism of acidic electrolyzed water focus on the effects of pH, oxidation-reduction potential (ORP), and available chlorine concentration (ACC) on microbial cell morphology, physiological and biochemical reactions. The bactericidal mechanism is generally believed to be the result of a combination of physical and chemical sterilization.

Research Progress on the Application of Acidic Electrolyzed Water in the Aquaculture Industry

1.1 Sterilization of Aquatic Raw Materials

Aquatic raw materials can carry foodborne pathogens. Acidic electrolyzed water, when used to treat these raw materials, not only disinfects them but also prevents environmental contamination from cleaning solutions and cross-contamination of aquatic raw materials, thereby reducing the risk of microbial contamination. Studies have shown that acidic electrolyzed water has a good killing effect on Listeria monocytogenes, Escherichia coli and Vibrio parahaemolyticus on the surface of aquatic products. For example, OZER et al. treated salmon with acidic electrolyzed water (pH = 2.6, ORP = 1 150 mV, ACC = 90 ppm) at 35 °C for 64 min. The results showed that Listeria monocytogenes in salmon decreased by 1.12 logarithms and Escherichia coli decreased by 1.07 logarithms. XIE et al. used acidic electrolyzed water to treat shrimp inoculated with Vibrio parahaemolyticus and found that the number of Vibrio parahaemolyticus on the surface of shrimp decreased by 2.12 logarithms after treatment at 50 °C for 1 min. MAHMOUD et al. used acidic electrolyzed water (pH = 2.22 ± 0.01, ACC = (40.8 ± 0.09) mg/L) to treat carp fillets and found that the total colony count decreased by 2.16 logarithms. Compared with the control group, acidic electrolyzed water can effectively kill microorganisms. Mo Yonggen et al. found that treating whiteleg shrimp with acidic electrolyzed water at 22 °C for 64 min could effectively kill microorganisms. min, the total bacteria on the surface of shrimp decreased by 0.86 logarithms; HUANG et al. used tilapia as the research object, treated it with acidic electrolyzed water at 25 ℃ for 10 min, and found that Escherichia coli decreased by 0.76 logarithms and Vibrio enteritidis decreased by 2.61 logarithms; Xu Yu et al. found that the use of acidic electrolyzed water with pH = 2.32 ± 0.01, ORP = (1 166.3 ± 2.6) mV, and ACC = (48 ± 2) μg/mL could completely kill Vibrio parahaemolyticus and reduce the number of Listeria monocytogenes by 1.45 logarithms; Li Xiuli et al. used cooked shrimp as the research object, and used acidic electrolyzed water to treat shrimp at a pH of 3.0, a material-liquid ratio of 1:2, and a soaking time of 25 min. The results showed that the total bacterial count decreased to 1.94 logarithms; PHUVASATE et al. studied the ice treatment of tuna with acidic electrolyzed water for 24 h, a 2.4-log reduction in aerobic Bacillus and a 3.5-log reduction in Morganella morganiana were observed.

1.2 Surface Sterilization of Processing Equipment

Aquatic products often come into contact with various equipment during processing, most of which is made of materials such as stainless steel, ceramic tile, and glass. Using acidic electrolyzed water to sterilize fishing equipment prevents cross-contamination between equipment and aquatic products. Acidic electrolyzed water sterilizes aquatic product processing equipment with excellent sterilization effectiveness and has broad application prospects in aquatic product processing enterprises. Studies have found that acidic electrolyzed water has a good killing effect on microorganisms on the surface of processing equipment made of materials such as stainless steel. For example, acidic electrolyzed water can kill all 10 CFU/mL of pathogenic bacteria in 1 minute; acidic electrolyzed water can kill all 10 CFU/cm2 of pathogens on the surface of processing equipment within 5 minutes; AYEBAH et al. found that the number of Listeria monocytogenes on the surface of stainless steel equipment was significantly reduced after being soaked in acidic electrolyzed water for 30 to 120 seconds; LIU et al. found that the cleanliness of the surface of equipment made of different materials will affect the bactericidal effect of acidic electrolyzed water, and organic matter will reduce the bactericidal effect of electrolyzed water; Shen Xiaosheng et al. artificially contaminated the surface of processing equipment and then disinfected it with acidic electrolyzed seawater. They found that 107 CFU/cm2 of pathogens were almost completely killed within 5 minutes; VENKITANARAYANAN et al. soaked cutting boards in oxidizing electrolyzed water at 35°C for 20 seconds. After 15 minutes, all E. coli O157:H7 on the cutting board was found to be inactivated. The study also found that E. coli and Listeria monocytogenes became reactivated in the deionized water used to soak the cutting board, but not in oxidizing electrolyzed water.

1.3 Disinfection of Aquaculture Environments

With the rapid development of the aquaculture industry, the aquaculture area and production scale have continued to expand. Problems such as deteriorating aquaculture environments, pathogen contamination, and deteriorating water quality have become increasingly prominent. This deteriorating aquaculture environment leads to the proliferation of pathogens. If pathogens are not effectively eliminated, residual pathogens can lead to deteriorating quality or even death of fish and shrimp. This not only causes significant economic losses to aquaculture farmers but also harms the health of consumers, hindering the development of the aquaculture industry.

Currently, most aquaculture farms use sterilization technologies such as ozone, chlorine dioxide, and ultraviolet light to purify water. Ozone is a strong oxidant, but controlling its amount, ensuring uniform dissolution in seawater and maintaining a stable concentration in the water presents challenges. Chlorine dioxide has a high sterilization efficiency, but it is easily decomposed by light and can produce toxic products such as aldehydes under special water conditions. The sterilization effect of ultraviolet light is affected by many factors. The irradiation intensity decreases with the increase of irradiation time, which weakens the sterilization effect. Acidic electrolyzed water has the characteristics of broad spectrum, high efficiency, safety, harmlessness, and environmental friendliness. It is simple to operate and low cost. Its application in aquaculture has advantages that other technical methods cannot match. Electrolyzed water prepared using deep sea water as raw material has a more effective sterilization effect. Using acidic electrolyzed water to sterilize and disinfect aquaculture ponds when changing pond water can reduce the number of potential pathogens. Among them, JORQUERA et al. [27] used farmed scallops as the research object and found that acidic electrolyzed water had a good killing effect on Vibrio anguillarum in the water body. When the seawater electrolysis current was ≥1.3A, almost all pathogens were inactivated, and the sterilization cost was low.

1.4 Storage and preservation of aquatic products

Acidic electrolyzed water has been widely used in the storage and preservation of aquatic products because of its instantaneous broad spectrum sterilization effect. Among them, Sun Jiangping et al. found through in vitro enzyme kinetic analysis that acidic electrolyzed water (pH=2.35±0.01, ORP=1 172.40±0.46 mV, ACC=(72±1) mg/L) can reduce the activity of polyphenol oxidase (PPO) during the blackening process of white shrimp, inhibit the formation of black spots, and extend the shelf life to 5 days; Lan Weiqing et al. found that acidic electrolyzed water treatment inhibited the increase of total volatile basic nitrogen (TVB-N) value, thiobarbituric acid (TBA) value, total bacterial count and pH value during the cold storage of hairtail. Among them, acidic electrolyzed water (pH=2.62±0.01, ORP=(1 149.1±0.6) mV, ACC=(41.5±0.7) mg/L) produced by electrolysis for 11 min mg/L) for optimal preservation. Fu Jiaojiao et al. analyzed the changes in the intestinal microbiome of whiteleg shrimp during storage at 0, 4, and 25°C. They found that treatment with 500 mg/L of acidic electrolyzed water reduced microbial diversity and altered the microbial community within the shrimp's intestines. Aquatic products are primarily stored in ice, a method that is not only costly but also prone to hardening, reducing freshness and diminishing their commercial and nutritional value. Creating ice or glaze with acidic electrolyzed water can maximize its broad-spectrum antibacterial properties and prolong their duration. For example, the research of Yao Xin et al. showed that acidic electrolyzed water ice (pH=2.38±0.01, ORP=(1 153.21±1.51) mV, ACC=(44±1) mg/L) would not have adverse effects on the sensory and texture of small yellow croaker during storage, but could significantly reduce its pH value, lipase and cathepsin D activities, and inhibit the growth of microbial counts; ZHAO et al. found that acidic electrolyzed water ice significantly delayed the degradation of myofibrillar protein in shrimp and inhibited the growth of putrefactive bacteria; Lin Ting found that acidic electrolyzed water ice could preserve shrimp, with little change in pH value, color, etc. The traditional plate count method and polymerase chain reaction-denaturing gradient gel electrophoresis (PCR-DGGE) showed that acidic electrolyzed water ice could effectively inhibit the increase of microbial counts in shrimp, reduce the diversity of pathogenic bacteria, and have a good effect on maintaining the myofibrillar structure of shrimp; Gao Meng et al. showed that at -18 At 40°C, glazing with acidic electrolyzed water (pH = 4.5, ORP = 836.5 mV, ACC = 31.7 mg/L) can reduce the total bacterial count in tuna during storage. In particular, between 0 and 160 days, the bacterial and E. coli counts in the tuna remain consistently low, showing a significant downward trend. This can prevent the tuna from "burning" during transportation and maintain its freshness.

Existing Problems and Solutions

The high available chlorine concentration and low pH of acidic electrolyzed water can corrode processing equipment and operators and adversely affect the surface of aquatic product ingredients. For example, Wang Ling's research found that while acidic electrolyzed water treatment can effectively inhibit pathogens on the surface of sturgeon and extend its shelf life, residual chlorine and other factors in the fish can cause color changes. Consequently, research on slightly acidic, neutral, and alkaline electrolyzed water has increased in recent years.

2.1 Slightly Acidic Electrolyzed Water, Neutral Electrolyzed Water, and Alkaline Electrolyzed Water

Slightly acidic electrolyzed water is a new sterilization and preservation technology. It is safe, efficient, residue-free, and pollution-free, and is now widely used in aquatic product preservation and pre-processing. Niu Huiping et al. studied the disinfection ability of slightly acidic electrolyzed water and strongly acidic electrolyzed water, and found that under the same effective chlorine concentration, slightly acidic electrolyzed water has a stronger killing ability against Escherichia coli and Staphylococcus aureus; Cen Jianwei et al. found that after tilapia was treated with slightly acidic electrolyzed water, the number of colonies on the fish surface was significantly reduced, and the shelf life was extended by 2 to 3 days compared with the control group; Li Guowei et al. used slightly acidic electrolyzed water to treat live fresh Japanese scallops, and found that the scallops in the groups treated with slightly acidic electrolyzed water for 2 minutes and 4 minutes had the highest survival rate, and the total number of bacteria in the Japanese scallops was reduced after treatment with slightly acidic electrolyzed water; Yu Futian et al. found that when tilapia was treated with slightly acidic electrolyzed water with an effective chlorine concentration of 35.00 mg/L, the sterilization rate reached (81.59±0.04)%; at the same time, neutral electrolyzed water and alkaline electrolyzed water have also been well applied. Among them, Xiang Siying et al. found that treating fresh grass carp with neutral electrolyzed water effectively preserved the quality of the fish and extended its shelf life by approximately 4 days. Liang Fengxue et al. used response surface methodology to determine the optimal process parameters for treating live tilapia with alkaline electrolyzed water: a pH of 10, a salinity of 8‰, and a treatment time of 60 minutes. Under these conditions, the bacteria reduction rate reached 94.1%.

2.2 Combining Slightly Acidic Electrolyzed Water with Other Treatment Methods

In addition, some researchers have combined slightly acidic electrolyzed water with other treatment methods to maximize their combined effects. Among them, XUAN et al. found that after squid was treated with slightly acidic electrolyzed water ice, the total bacterial count in its body was significantly reduced, and its browning and softening were inhibited, so that its freshness was maintained; KIM et al. treated saury with slightly acidic electrolyzed water ice at 4°C, indicating that slightly acidic electrolyzed water ice can effectively inhibit the growth and reproduction of aerobic psychrophilic bacteria in saury and the fat oxidation of the fish body, maintain its good sensory quality, and extend its shelf life by 4 to 5 days compared with tap water ice storage. YEN et al. treated Macrobrachium rosenbergii with slightly acidic electrolyzed water (pH = 5.92, ORP = 810 mV, ACC = 20 mg/L) combined with ascorbic acid and found that its shelf life was extended by 3 days during storage at 4°C. Zheng Wei et al. studied Litopenaeus vannamei shrimp using a combination of slightly acidic electrolyzed water glaze and modified atmosphere packaging, finding that the shrimp's color was effectively maintained during freezing. Weakly acidic glazes adversely affected the volatile odor of raw shrimp but had no effect on cooked shrimp.

Prospects and Outlook

Consumers have increasingly higher requirements for the quality of aquatic products. Aquatic product preservation technology will have three development trends:

(1) Aquatic product preservation technology will focus more on being environmentally friendly, leaving no residue, and not causing potential harm to the human body;

(2) Aquatic product preservation technology will develop in the direction of using a variety of preservation technologies in combination. Different preservation technologies can make up for each other's shortcomings. The combined use can more effectively and efficiently ensure the quality of aquatic products and extend their shelf life;

(3) Aquatic product preservation technology will develop in a direction that is not restricted by seasons or regions, and pays more attention to practical operability and energy saving.

Acidic electrolyzed water is safe and non-toxic to the human body and is environmentally friendly, which is in line with the development trend of aquatic product preservation technology. Relevant research shows that it has a significant effect on the sterilization and preservation of aquatic products, can inhibit the growth and reproduction of bacteria in aquatic products, and has little effect on their sensory and nutritional properties. With the improvement of scientific and technological levels and the development of aquatic product preservation technology, acidic electrolyzed water will have broad application prospects in the sterilization and preservation of aquatic products due to its advantages of high efficiency, safety, and broad spectrum. Therefore, future research on the sterilization effects of acidic electrolyzed water in the aquaculture industry can be strengthened. Electrolyzed water of varying concentrations can be prepared based on the sterilization requirements of aquatic products at different stages of their growth. Furthermore, in aquaculture water sterilization and aquatic product cleaning and sterilization, sterilization kinetics analysis can be conducted on different aquatic products during their application to determine suitable initial characteristic parameters, reaction time, and other process conditions for acidic electrolyzed water. This can further reduce the cost and energy consumption of acidic electrolyzed water production equipment and ensure optimal sterilization results. Furthermore, barrier technology can be utilized to organically combine acidic electrolyzed water with other treatment technologies to maximize its sterilization and preservation properties. Governments, research institutions, and related companies can also work together to improve standards and specifications related to the use of acidic electrolyzed water technology, conduct in-depth research on the sterilization and preservation mechanisms of acidic electrolyzed water, and further promote its application in the sterilization and preservation of aquatic products.

Above Article Source: http://sf1970.cnif.cn/fileup/0253-990X/HTML/2020-4-294.shtml

Chlory's hypochlorous acid generator (HClO Generator) is an advanced disinfection device that uses electrolysis to convert salt and water into high-purity hypochlorous acid (HClO). It is widely used in healthcare, food processing, water treatment, and public health. Hypochlorous acid is a highly effective, broad-spectrum disinfectant that quickly kills bacteria without leaving any harmful residue, making it an ideal alternative to traditional chlorine-based disinfectants.

Widely exported to Australia, Libya, Italy, etc.