The core objective of power plant water treatment is to remove impurities (such as suspended solids, colloids, dissolved salts, organic matter, microorganisms, etc.) from raw water, so that the water quality meets the usage requirements of different power generation links. According to water usage scenarios, power plant water quality standards are mainly divided into three categories:boiler feedwater standards(requiring extremely high purity, almost free of dissolved salts and impurities),circulating cooling water standards(controlling scaling and corrosion factors), andash and slag flushing water standards(needing to remove suspended solids to avoid pipeline blockage).

Core Objectives and Importance of Power Plant Water Treatment Process

An efficient water treatment process can bring multiple benefits: first, it reduces equipment maintenance costs and decreases the maintenance frequency caused by scaling and corrosion; second, it improves energy conversion efficiency—for example, 1mm of boiler scaling will increase coal consumption by 2%-5%; third, it meets environmental protection requirements, realizing the recycling and up-to-standard discharge of water resources.

Analysis of the Complete Power Plant Water Treatment Process

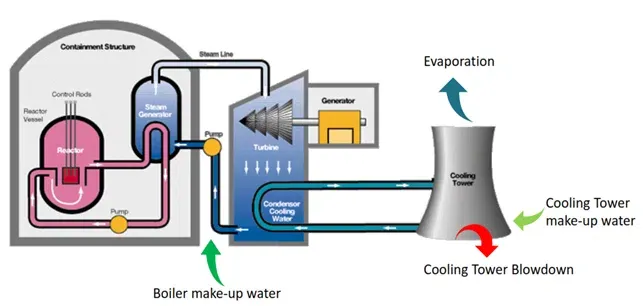

The power plant water treatment process is usually divided into four stages:pretreatment, advanced treatment, steam-water cycle treatment, and wastewater treatment. Each stage is interconnected to jointly ensure water quality safety.

Stage 1: Pretreatment – Removal of Suspended and Colloidal Impurities in Water

Pretreatment is the first line of defense in water treatment, aiming to remove large-particle suspended solids, colloids, sediment, and part of organic matter from raw water, reducing the load for subsequent advanced treatment. The main steps include:

- Coagulation and Sedimentation: Add coagulants (such as polyaluminum chloride, aluminum sulfate) and flocculants (such as polyacrylamide) to raw water to make fine suspended solids and colloids aggregate into larger flocs, which are separated by sedimentation in a sedimentation tank. This step can remove more than 80% of suspended solids and part of colloidal impurities.

- Filtration: The precipitated water enters filters (such as quartz sand filters, activated carbon filters) to further intercept remaining fine particles and organic matter. Activated carbon filters can also adsorb odors, pigments, and part of heavy metal ions in water.

- Sterilization: If the microbial content in raw water is high, sodium hypochlorite or chlorine dioxide needs to be added for sterilization to prevent microorganisms from breeding in subsequent equipment to form biological slime.

Stage 2: Advanced Treatment – Preparation of High-Purity Boiler Feedwater

The water after pretreatment still contains a large amount of dissolved salts and cannot be directly used as boiler feedwater, so it is necessary to remove ionic impurities through advanced treatment. The current mainstream technology is thereverse osmosis + ion exchangecombined process:

- Reverse Osmosis (RO): Utilize the selective permeability of semi-permeable membranes to allow water to pass through the membrane under high pressure, while dissolved salts, organic matter, etc., are intercepted. Reverse osmosis can remove more than 98% of dissolved salts and more than 90% of organic matter, which is the core link of advanced treatment. During operation, membrane elements need to be cleaned regularly to prevent scaling and contamination.

- Ion Exchange: The reverse osmosis product water enters ion exchangers (cation bed, anion bed, mixed bed) to further remove remaining trace ions. The cation bed removes cations in water (such as Ca²⁺, Mg²⁺, Na⁺), the anion bed removes anions (such as Cl⁻, SO₄²⁻, HCO₃⁻), and the mixed bed mixes cation exchange resin and anion exchange resin in proportion to achieve deep desalination, making the product water resistivity reach 10-18MΩ·cm, which meets the water requirements of high-pressure boilers.

Stage 3: Steam-Water Cycle Treatment – Maintaining Stable Circulating Water Quality

Most of the steam generated by the boiler condenses into condensed water after doing work in the turbine, which needs to be treated before being returned to the boiler for recycling. This process is called steam-water cycle treatment. The key steps include:

- Condensed Water Polishing: Condensed water may contain a small amount of corrosion products (such as iron and copper oxides) and dissolved salts, which need to be removed by mixed bed filters to ensure the purity of recycled water.

- Boiler Dosing Treatment: Add chemicals such as phosphate and ammonia to boiler water to adjust the pH value of water, prevent boiler scaling and pipeline corrosion, and inhibit steam from carrying salts.

- Steam Quality Monitoring: Real-time monitor the salt content and impurity content in steam. If it exceeds the standard, the water treatment process should be adjusted in time to avoid turbine salt accumulation affecting efficiency.

Stage 4: Wastewater Treatment – Realizing Environmental Protection Discharge and Water Resource Recycling

Various types of wastewater are generated during the operation of power plants, such as acid-base wastewater, oily wastewater, ash flushing wastewater, etc., which need to be treated to meet standards before discharge or recycling:

- Acid-Base Neutralization Treatment: For acid-base wastewater generated from ion exchange regeneration, add acid-base chemicals through a neutralization tank to adjust the pH value to the discharge standard of 6-9.

- Oily Wastewater Treatment: Use oil separation tanks and air flotation machines to remove floating oil and emulsified oil from wastewater, and then further purify it through biological treatment or filtration.

- Reclaimed Water Reuse: The treated wastewater can be used as supplementary water for circulating cooling water or ash and slag flushing water, realizing the recycling of water resources and reducing the consumption of fresh water.

Key Technology Trends and Optimization Suggestions for Power Plant Water Treatment

With the improvement of environmental protection requirements and technological development, power plant water treatment is developing towardsintelligence, energy conservation, and resource utilization. For example, membrane separation technology (such as ultrafiltration and nanofiltration) is used to replace traditional filtration processes to improve impurity removal efficiency; automatic control systems are introduced to monitor water quality indicators in real-time and automatically adjust chemical dosage and equipment operation parameters; "zero discharge" technology is promoted to convert wastewater into solid waste through evaporation and crystallization, realizing the complete recycling of water resources.

For power plants, the following points should be noted to optimize the water treatment process: first, select appropriate process combinations according to the characteristics of raw water quality to avoid over-treatment or insufficient treatment; second, strengthen equipment maintenance, regularly clean filters, replace membrane elements and resins to ensure efficient operation of equipment; third, establish a sound water quality monitoring system to realize full-process quality control.

The power plant water treatment process is the "lifeline" of power production, covering multiple links such as pretreatment, advanced treatment, steam-water cycle treatment, and wastewater treatment. Each step is crucial for ensuring unit safety and improving efficiency. In the future, with continuous technological innovation, power plant water treatment will achieve greater breakthroughs in environmental protection and economy. Mastering the scientific water treatment process and technical points is the key for power plants to realize sustainable development.