Driven by the accelerating transformation of the global energy structure and increasingly stringent ecological environmental protection, the power generation industry is undergoing a profound shift from traditional models to green and sustainable development. Against this backdrop, seawater electrochlorination technology, with its efficient utilization of seawater resources and unique environmental attributes, is gradually emerging as a key technology driving the green transformation of the power generation industry. Among them, the electrolytic seawater hypochlorous acid generator developed by Chlory is a typical application of this technology, offering new solutions to address environmental and efficiency challenges in power generation processes.

Core Principles of Seawater Electrochlorination Technology

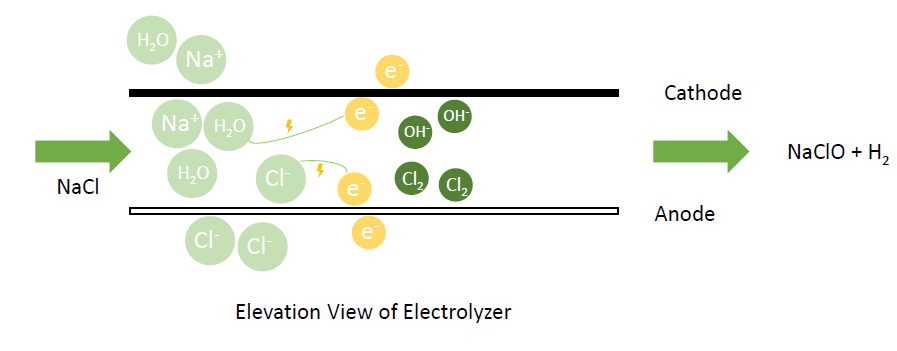

The core of seawater electrochlorination technology lies in converting the abundant chloride ions (Cl⁻) in seawater into sodium hypochlorite (NaClO) through an electrolysis process. As a powerful oxidizing agent, sodium hypochlorite not only possesses excellent bactericidal and disinfecting capabilities but also exhibits high efficiency in treating industrial wastewater and inhibiting biological adhesion, demonstrating multiple practical values in industrial scenarios.

Unlike traditional chlorine treatment methods, this technology directly uses on-site seawater at power generation facilities as raw material for electrolysis, eliminating the need for transportation and storage of traditional chlorine gas or liquid bleach. This characteristic fundamentally avoids the risks of leakage during transportation and safety hazards in storage of chemical agents, significantly enhancing operational safety and convenience, and providing inherent advantages for on-site applications.

In-depth Application Practices in the Power Generation Industry

Biofouling Prevention and Control in Cooling Systems

In coastal power plants, seawater is often used as a medium in cooling systems due to its easy accessibility and good cooling performance. However, a large number of microorganisms, algae, and other organisms in seawater tend to attach and grow on the inner walls of pipes, forming biofouling. This not only reduces the heat dissipation efficiency of pipes, leading to increased energy consumption of units, but also accelerates equipment corrosion, shortens service life, and raises maintenance costs.

The sodium hypochlorite solution produced by seawater electrochlorination technology can accurately kill microorganisms in seawater and inhibit their regeneration, blocking the formation of biofouling at the source. For example, after some coastal power plants introduced this technology, the maintenance intervals of cooling systems were extended from the original 3 months to 6-8 months, the operational efficiency of equipment increased by approximately 15%, stability was significantly enhanced, and the comprehensive energy consumption of units was indirectly reduced.

Wastewater Treatment and Support for Zero-Emission Goals

Wastewater generated during power generation contains various pollutants such as heavy metals and organic substances, and direct discharge can cause severe damage to the surrounding ecology. Seawater electrochlorination technology generates sodium hypochlorite by electrolyzing chloride ions in wastewater, which not only enables deep disinfection and purification of wastewater but also allows the sodium hypochlorite to be recycled in subsequent treatment stages, forming a "electrolysis-purification-reuse" closed-loop system.

This model not only reduces the purchase volume of chemical agents and lowers treatment costs but also promotes the resource recovery of wastewater—treated wastewater can be used for factory greening, equipment flushing, etc., helping power generation enterprises move toward "zero-emission" goals.

Technical Advantages and Value in Green Transformation

Compared with traditional chemical treatment methods, seawater electrochlorination technology has particularly prominent advantages:

- Environmental friendliness: Reduces the use of chemical agents and minimizes secondary pollution to the ecological environment;

- Economic efficiency: Eliminates costs related to transportation and storage of chemical agents, reduces equipment maintenance frequency, and lowers overall operating costs by approximately 20%;

- Safety and reliability: Avoids risks associated with the circulation of hazardous chemicals and improves the safety level of on-site operations;

- Flexible adaptability: Can adjust electrolysis parameters according to the actual needs of power plants, adapting to the treatment requirements of units of different scales. Driven by the "dual carbon" goals, this technology provides practical solutions for energy conservation and emission reduction in the power generation industry, serving as a crucial support for green transformation.

Future Prospects and Development Directions

With the continuous maturity of the technology, the application scope of seawater electrochlorination technology is expanding. In the future, it is expected to deeply integrate with the Internet of Things (IoT) and intelligent control systems to achieve precise regulation and remote monitoring of the electrolysis process, further improving operational efficiency. Meanwhile, beyond the power generation industry, the technology's application potential in marine engineering, chemical industry, municipal wastewater treatment, and other fields will gradually be unleashed.

In the long run, seawater electrochlorination technology is not only a "powerful tool" to address the contradictions between environmental protection and efficiency in the power generation industry but will also become an important technical benchmark for practicing the concept of green development in the global industrial sector. On the path of synergistic development between efficient utilization of seawater resources and ecological protection, this technology will undoubtedly write a more influential chapter.