Industrial cooling water system is the core facility of thermal power generation, chemical production, steel smelting and other industries. Its water quality management directly affects equipment efficiency and operation safety. The BSHH series of sodium hypochlorite generators produced by Bluewavw Company generates high-concentration sodium hypochlorite on-site through electrolytic salt.

Sodium hypochlorite (NaClO) has become an important treatment agent in this field due to its high-efficiency sterilization, corrosion and scale inhibition and water quality optimization capabilities. The specific applications are as follows:

I. Microbial control and biofilm inhibition

Bactericidal and algae killing mechanism

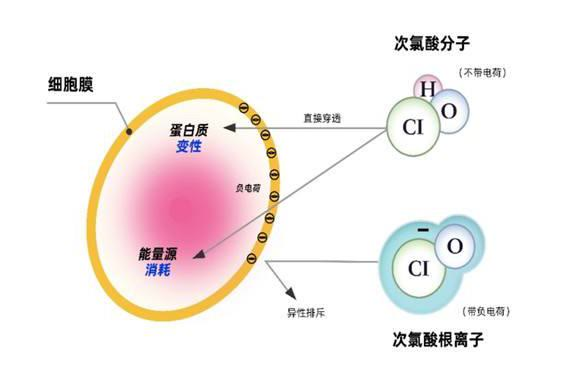

Sodium hypochlorite generates hypochlorous acid (HClO) and new ecological oxygen through hydrolysis, destroys the cell membrane structure of microorganisms and oxidizes their DNA/mitochondria, and achieves broad-spectrum inactivation of bacteria (including Legionella), algae and viruses. In high-temperature circulating cooling water, its sterilization efficiency can reach more than 99%, effectively preventing the attachment of biofilm to the inner wall of the pipe, and avoiding the decrease in heat transfer efficiency and equipment blockage caused by microbial proliferation.

Synergistic disinfection strategy

Sodium hypochlorite can be used in combination with hydrogen peroxide or ozone to synergistically enhance the sterilization effect through redox potential (ORP). For example, in the circulating water system of a power plant, sodium hypochlorite is used in combination with a neutralizing agent (such as sodium hydroxide) to adjust the pH value to 6.5-7.5, reducing the inhibition of the bactericidal activity by the high pH environment.

2. Water quality optimization and system maintenance

Organic matter and odor control

Sodium hypochlorite oxidizes and decomposes pollutants such as sulfide and ammonia nitrogen in water, eliminating the humic acid odor caused by microbial metabolism. In the scenario where printing and dyeing wastewater is reused in the cooling system, sodium hypochlorite can also achieve partial COD degradation and decolorization, but the dosage needs to be controlled to avoid sludge activity inhibition.

Scale and corrosion inhibition function

Sodium hypochlorite reacts with calcium and magnesium ions to form soluble complexes, reducing the deposition of scale such as calcium carbonate and calcium sulfate, and extending the service life of heat exchangers and cooling tower fillers. At the same time, by maintaining the residual chlorine concentration of 0.1-0.5ppm, the corrosion rate of carbon steel and copper alloy pipes can be reduced while sterilizing.

III. Typical application scenarios and operating specifications

Thermal power plant circulating water system

The thermal power plant has a large amount of circulating water (a single unit can reach 50,000 tons/hour). The sodium hypochlorite generator can electrolyze salt water on-site to produce disinfectant, and continuously add it at an effective chlorine concentration of 5-15mg/L to achieve dynamic control of microorganisms.

Image:

Chemical and metallurgical industry

In the closed cooling tower of a chemical plant, sodium hypochlorite removes ammonia nitrogen through the "breakpoint chlorination method" (reaction formula: 2NH₃ + 3NaClO → N₂↑ + 3H₂O + 3NaCl), avoiding the formation of carcinogenic chloramine compounds by ammonia nitrogen and chlorine.

Key points of operation

Dosing method: Continuous dosing with a metering pump is preferred, and intermittent impact dosing is suitable for scenes with explosive microbial proliferation.

Concentration monitoring: The online residual chlorine meter (such as PRM-2000α refractometer) is used to monitor the effective chlorine content in real time, and the error must be less than ±0.1ppm.

Safety protection: Operators need to wear goggles and acid-resistant gloves to prevent sodium hypochlorite from contacting acidic substances and causing chlorine gas to escape.

IV. Economic benefits and environmental advantages

Cost advantages

The preparation cost of sodium hypochlorite is about 0.5-1.2 yuan/kg (in terms of effective chlorine), which reduces the operating cost by 30%-50% compared with disinfectants such as chlorine dioxide and ozone. The salt utilization rate of the electrolysis process (such as the source intelligent generator) is greater than 95%, and the annual maintenance cost is lower than that of the traditional liquid chlorine system.

Environmental friendliness

The decomposition products of sodium hypochlorite are mainly sodium chloride and water, without persistent toxic residues, which meets the environmental protection requirements of the "Design Specification for Industrial Circulating Cooling Water Treatment" (GB 50050).

Conclusion

The application of sodium hypochlorite in industrial cooling water has formed a comprehensive solution of sterilization, scale inhibition, corrosion inhibition and water purification. Bluewav has been committed to the research and development and production of sodium hypochlorite generators. With the popularization of online monitoring technology and high-efficiency generators, its value in improving the energy efficiency of industrial water systems and reducing operation and maintenance costs will be further highlighted. In the future, it is necessary to focus on the optimization of reagent stability in high-salt wastewater scenarios and the precise control technology of intelligent dosing systems.