In recent years, the global shipping industry has shown explosive growth, and port infrastructure is facing unprecedented challenges. Equipment corrosion and pipeline blockage caused by marine biological attachment are frequent, and the risk of cross-regional transmission of harmful aquatic organisms and pathogens is increasing. With its efficient disinfection ability and environmentally friendly characteristics, the seawater electrochlorination system has become a key technology to solve the difficulties of port operations. Chlory's seawater electrochlorination system application strategy in port scenarios provides a feasible path for building a green, safe and efficient modern port operation system.

Overview of seawater electrochlorination system

(I) Working principle

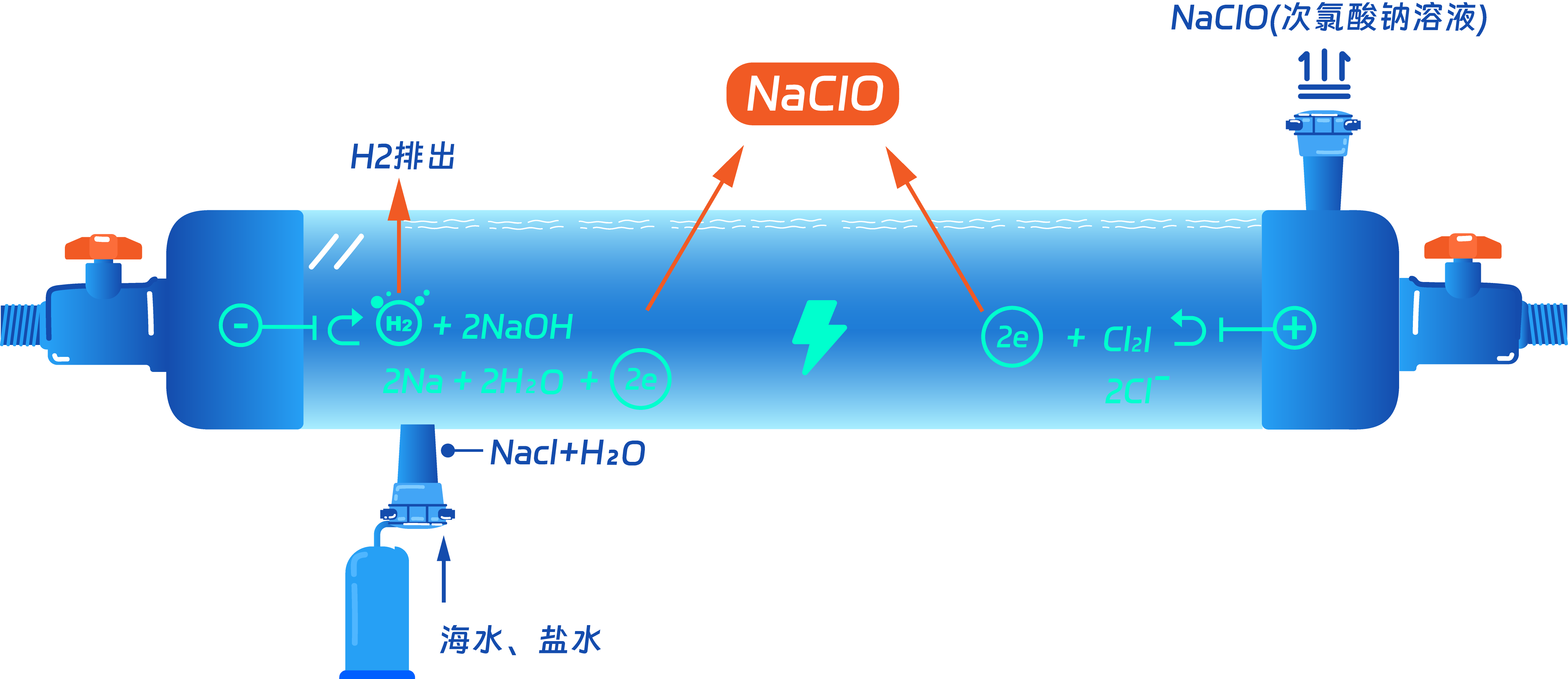

The seawater electrochlorination system produces highly oxidizing sodium hypochlorite (NaClO) or chlorine (Cl₂) by electrolyzing seawater. During the electrolysis process, the sodium chloride (NaCl) in the seawater undergoes an electrochemical reaction under the action of the electric field. Taking the production of sodium hypochlorite as an example, an oxidation reaction occurs at the anode: 2Cl⁻ - 2e⁻ = Cl₂↑, and the generated chlorine reacts with water: Cl₂ + H₂O ⇌ HCl + HClO, and HClO further reacts with sodium hydroxide (NaOH) in seawater to generate sodium hypochlorite: HClO + NaOH = NaClO + H₂O. These strong oxidizing substances can effectively kill bacteria, viruses, algae and other marine organisms in seawater, thereby achieving the purpose of disinfection and anti-fouling.

(II) System composition

Electrolysis device: core components, usually composed of anode, cathode and electrolytic cell. Anode materials mostly use dimensionally stable anode (DSA), such as ruthenium (Ru) and iridium (Ir) based composite metal oxides, which have good corrosion resistance and chlorine evolution performance. The cathode is generally made of stainless steel and other materials. The design of the electrolytic cell must ensure that seawater can flow evenly between the electrodes to improve the electrolysis efficiency.

Control system: used to monitor and adjust various parameters in the electrolysis process, such as current, voltage, electrolysis time, etc. Through automatic control, the system can be ensured to operate stably according to the actual needs of seawater quality, processing volume, etc., and the amount of disinfectant generated can be accurately controlled.

Dosing device: Sodium hypochlorite or chlorine gas generated by electrolysis is accurately added to the seawater to be treated according to the set dosage. The dosing device has the functions of precise metering and adjustable flow to meet the disinfection needs in different scenarios.

Monitoring equipment: Real-time monitoring of key parameters such as residual chlorine content, pH value, and temperature in seawater. Residual chlorine monitoring can intuitively reflect the disinfection effect. Parameters such as pH value and temperature will affect the electrolysis efficiency and the stability of the disinfectant. By monitoring these parameters, the system operating parameters can be adjusted in time to ensure that the system is always in the best operating state.

(III) Advantages

On-site chlorine production: Directly use the abundant seawater in the port as raw material to generate disinfectants on site, without the need to store and transport a large amount of externally purchased chemical disinfectants, which greatly reduces the transportation and storage risks, and at the same time reduces logistics costs and management difficulties.

Highly efficient sterilization and algae removal: Sodium hypochlorite and chlorine have strong oxidizing properties, which can quickly destroy the cell structure of microorganisms, and have significant killing effects on various bacteria, viruses, algae and marine organisms, effectively preventing the attachment and breeding of marine organisms on port facilities, and ensuring the normal operation of port equipment.

Environmentally friendly and sustainable: Compared with traditional chemical disinfection methods, the disinfectant produced by the seawater electrochlorination system will gradually decompose after use, will not accumulate harmful substances in the environment, and has less impact on the marine ecological environment, which is in line with the concept of sustainable development. In addition, reducing the transportation and storage of chemical disinfectants will also help reduce carbon emissions and contribute to environmental protection.

Cost-effectiveness: In the long run, the operating cost of the seawater electrochlorination system is relatively low. Although the initial investment in the equipment is large, since there is no need to frequently purchase chemical disinfectants and the equipment maintenance is relatively simple, a lot of operating expenses can be saved over time. At the same time, reducing the equipment maintenance and replacement costs caused by the attachment and corrosion of marine organisms further improves economic benefits.

Port application scenario analysis

(I) Ship ballast water treatment

When ships sail between different ports, in order to ensure navigation safety and stability, ballast water needs to be discharged and injected. However, ballast water often carries a large number of marine organisms and pathogens. If it is discharged to other ports at will, it may cause serious damage to the local ecological environment and cause problems such as biological invasion. The seawater electrochlorination system can treat ballast water during the ship's berth. By setting up a special ballast water treatment facility in the port, the seawater electrochlorination system is integrated into it. When the ship needs to treat ballast water, the ballast water is introduced into the treatment facility, and after disinfection by the seawater electrochlorination system, it is discharged to the designated area. This can effectively kill harmful organisms in ballast water, prevent them from spreading between different ports, and protect the balance of the local marine ecosystem.

(II) Anti-fouling of port cooling system

Many equipment in the port, such as power equipment, mechanical equipment, etc., need to be cooled with seawater. During long-term use, microorganisms and algae in seawater are easy to attach and grow on the surface of cooling pipes and equipment, forming biofouling, reducing cooling efficiency, increasing energy consumption, and even causing equipment failure. The seawater electrochlorination system can be used at the water inlet of the port cooling system to pre-treat the seawater entering the cooling system. By continuously adding an appropriate amount of sodium hypochlorite or chlorine to the cooling water, the growth of microorganisms and algae is inhibited, the formation of biofouling is prevented, the efficient and stable operation of the cooling system is ensured, the service life of the equipment is extended, and the cost of equipment maintenance and replacement is reduced.

(III) Disinfection of port waters

Port waters are frequently visited by people and have intensive ship activities, which are easily contaminated by various pathogens. The seawater electrochlorination system can be used to regularly disinfect port waters and improve the sanitary environment of port waters. For example, in areas with more personnel activities such as passenger terminals and yacht terminals, as well as waterways and anchorages in ports, the disinfectant produced by the seawater electrochlorination system is evenly added to the water body by reasonably arranging the dosing points to kill bacteria, viruses and other pathogens in the water, reduce the risk of infectious diseases, and ensure the health and safety of port staff and tourists.

Application solution design

(I) System selection and scale determination

According to the port demand assessment: Detailed investigation of key data such as the number and type of ships entering and leaving the port, the amount of ballast water discharged, the water consumption of the cooling system, and the area of the port waters. For ship ballast water treatment, the average daily number of ships of different tonnage arriving at the port is counted to estimate the total ballast water treatment capacity; for the cooling system, the cooling water demand and operating time of each equipment are understood; for port water disinfection, the scope of waters that need to be disinfected and the disinfection frequency are clarified.

Water quality analysis: Collect seawater samples from different areas of the port and analyze water quality indicators such as salinity, pH value, turbidity, and microbial content. These indicators will affect the electrolysis efficiency and disinfectant generation of the seawater electrochlorination system, thereby providing an important basis for system selection. For example, seawater with higher salinity may be more conducive to the electrolysis of sodium hypochlorite, but excessive turbidity may affect the service life of the electrode, which needs to be considered in the system design.

Determine the scale of the system: According to the port demand assessment and water quality analysis results, combined with the treatment capacity and efficiency of the seawater electrochlorination system, determine the scale and model of the system. For ports with large treatment volumes, a large-scale system with multiple electrolysis devices in parallel can be selected to meet the needs of simultaneously treating a large amount of ballast water or cooling water; for ports with smaller treatment volumes, a small and compact system can be selected to reduce equipment investment costs. At the same time, considering the future development of port business and the growth of demand, a certain amount of expansion space should be reserved when designing the system.

(II) System layout and installation

Layout of ship ballast water treatment facilities: A special ship ballast water treatment area is set up at a suitable location in the port. The area should be close to the ship's berthing terminal to facilitate the ship to connect to the ballast water delivery pipeline. The electrolysis device, control system, dosing device and monitoring equipment of the seawater electrochlorination system are centrally installed in an independent treatment workshop to ensure the safe operation of the equipment and facilitate maintenance and management. The design of the treatment workshop should comply with relevant building specifications and safety standards and have good ventilation, drainage and fire prevention facilities. At the same time, a ballast water storage tank is set up to temporarily store ballast water before and after treatment to ensure the continuity and stability of the treatment process.

Port cooling system installation: The seawater electrochlorination system is installed near the water inlet pipeline of the port cooling system. According to the layout of the cooling system and the water consumption, the location of the electrolysis device and the dosing point is reasonably determined. The electrolysis device is usually installed near the cooling water pump so that the pressure of the water pump can be used to make the seawater pass through the electrolytic cell evenly. Dosing points should be set at multiple locations in the cooling pipeline to ensure that the disinfectant can be fully mixed with the cooling water flow and cover the entire cooling system. During the installation process, attention should be paid to the connection and sealing of the pipeline to prevent seawater leakage and system failure.

Arrangement of disinfection dosing points in port waters: Dosing points should be reasonably arranged according to factors such as the topography, water flow direction and personnel activity area of the port waters. In densely populated dock areas, channel intersections and areas where the water flow is slow and microorganisms are easy to breed, the dosing points should be increased; in open waters and areas with faster water flow, the dosing points should be appropriately reduced. Dosing points can be fixed or mobile. Fixed dosing points are connected to the seawater electrochlorination system through pipelines to inject disinfectants directly into the water body; mobile dosing points can be equipped with dosing equipment on ships to flexibly add drugs in different waters as needed. At the same time, water quality monitoring equipment is used to monitor the residual chlorine content of water bodies in various areas in real time, and the dosing dosage and frequency are adjusted according to the monitoring results.

(III) Operation management and maintenance

Establish an operation management system: formulate detailed seawater electrochlorination system operation and operation procedures, and clarify the responsibilities and work processes of operators. The system startup, shutdown, operating parameter adjustment and daily inspection procedures are specified to ensure the stable operation of the system. An operation record system is established to record the system's operating data, such as current, voltage, residual chlorine content, and water volume, in real time, to facilitate the analysis of the system's operating status and timely detection of problems. At the same time, an emergency plan is formulated to formulate corresponding response measures for possible equipment failures, power outages, abnormal water quality and other emergencies to ensure the normal operation of port-related businesses.

Equipment maintenance: Regularly maintain the equipment of the seawater electrochlorination system to extend the service life of the equipment. The electrodes of the electrolysis device are consumable parts. The degree of corrosion of the electrodes should be checked regularly according to the usage, and they should be cleaned or replaced in time. Calibrate and maintain the instruments, sensors and other equipment of the control system to ensure the accuracy of their measurement data. Check whether the pipes and valves of the dosing device are blocked or leaking, and clean and repair them in time. Regularly clean and maintain the equipment in a comprehensive manner to prevent seawater corrosion and debris accumulation from affecting equipment performance. At the same time, establish equipment maintenance files to record the maintenance of the equipment and provide a basis for the management and update of the equipment.

Personnel training: Provide professional training to personnel who operate and maintain the seawater electrochlorination system to familiarize them with the working principle, operation method and maintenance points of the system. The training content includes equipment start-up and stop, parameter setting and adjustment, fault diagnosis and troubleshooting, safe operating procedures, etc. Improve the technical level and operation ability of personnel through a combination of theoretical learning and practical operation. Regularly organize personnel to conduct technical exchanges and training assessments to continuously improve the professional quality of personnel and ensure that the system can be correctly and effectively operated and maintained.

Cost-benefit analysis

(I) Cost analysis

Equipment procurement and installation costs: The equipment procurement costs of the seawater electrochlorination system mainly include the costs of electrolysis devices, control systems, dosing devices, monitoring equipment, and related pipes, valves and other accessories. The price of equipment varies depending on the brand, model, processing capacity and technical level. Installation costs include equipment transportation, installation and commissioning, and civil engineering costs. For large ports, the equipment procurement and installation costs may be high, but through reasonable bidding and project management, costs can be effectively controlled.

Operating costs: Operating costs mainly include electricity costs, equipment maintenance costs, and employee wages. The seawater electrochlorination system is an energy-consuming device. The electrolysis of seawater requires a large amount of electricity, and electricity costs account for a large proportion of the operating costs. Equipment maintenance costs are mainly used for regular replacement of electrodes, repair of equipment failures, and purchase of consumables. In addition, professional operators and maintenance personnel are required, and employee wages are also part of the operating costs.

Other costs: such as system upgrade and transformation costs, water quality monitoring costs, etc. With the continuous advancement of technology and changes in port needs, it may be necessary to upgrade the seawater electrochlorination system to improve the performance of the system and adapt to new requirements. Water quality monitoring costs are used to regularly test the seawater quality and treated water quality to ensure that the system's operating effect and water quality meet relevant standards.

(II) Benefit Analysis

Environmental benefits: The seawater electrochlorination system is used to treat ship ballast water, port cooling system water, and port waters, effectively preventing the spread of harmful aquatic organisms and pathogens, protecting the local marine ecological environment, and reducing the damage and economic losses caused by biological invasions to the ecosystem. At the same time, the use and discharge of chemical disinfectants are reduced, reducing pollution to the environment, and having significant environmental benefits.

Economic benefits: In the long run, seawater electrochlorination systems can reduce the operating costs of ports. Reduce equipment maintenance and replacement costs caused by marine biological attachment and corrosion, increase equipment life and operating efficiency, and reduce energy consumption. In addition, legal disputes and economic compensation caused by environmental problems such as biological invasion are avoided, providing a guarantee for the sustainable development of ports. At the same time, a good port environment helps to attract more ships to dock, promote the development of port business, and increase port revenue.

Social benefits: It ensures the health and safety of port staff and tourists, and reduces the risk of infectious diseases spreading in the port area. It enhances the image and competitiveness of the port and contributes to local economic development and social stability.

Conclusion

The application of seawater electrochlorination systems in ports has significant advantages and broad prospects, and can effectively solve the problems of marine biological attachment, harmful aquatic organism transmission and water pollution faced by ports. Through reasonable system selection, layout installation, scientific operation management and maintenance, combined with comprehensive cost-benefit analysis, it can ensure that the seawater electrochlorination system can achieve efficient and stable operation in the port, providing strong technical support for the sustainable development of the port. Chlory has been committed to the research and development and production of seawater electrochlorination systems. In future port construction and operations, seawater electrochlorination systems should be actively promoted and applied to continuously optimize system performance and improve the comprehensive management level and environmental quality of ports.