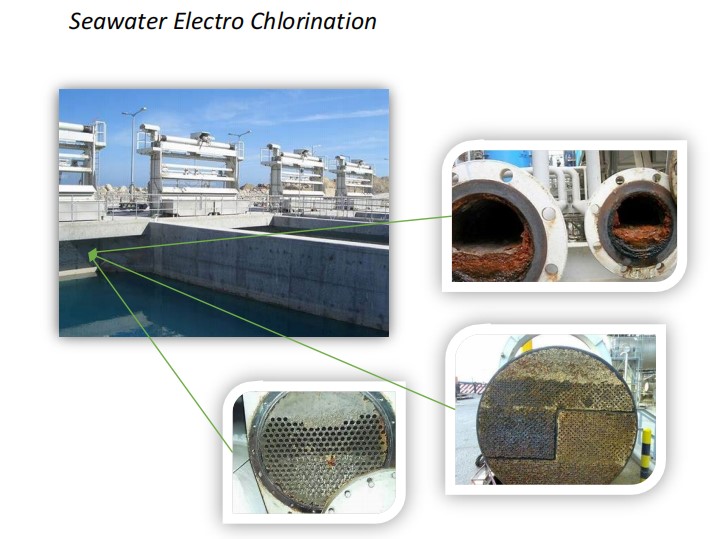

The development of offshore oil must first remove two major obstacles, that is, the attachment of Marine fouling organisms and the corrosion of metals in seawater. Because sea organisms can grow and reproduce on water objects, it is harmful to ships and Marine buildings, so it is necessary to useBLUEWAV electrolytic seawater low-concentration sodium hypochlorite generatorfor treatment.

Marine biological corrosion hazards

There are more than 2000 species of these sea creatures. Common sea creatures in the coastal zone are coelenterates, ectoanal animals, arthropods, annelids, molluscs, bursids, ship bores, algae, shellfish, microorganisms, etc. Among them, microorganisms in the metabolic activities of life, will produce a variety of chemical substances, which produced acid is very corrosive to metals; Microbes also produce a variety of other metabolites, which are highly corrosive to metals; Some microbial fungi and algae close to the local surface of the metal, resulting in oxygen concentration, with the consumption of microorganisms on oxygen, concentration will be aggravated, due to the oxygen concentration of the battery, so that the metal is subjected to local corrosion: microbial corrosion will also destroy the metal surface of the oxide protective film, stainless steel and Marine grade aluminum are dependent on this oxide protective film and have corrosion, Microorganisms and other fouling organisms stick to the surface of such metals to grow and reproduce, consume oxygen, cause local anoxic zone, and destroy the oxide film, thereby causing pitting.

It can be seen from the above introduction that the harm of Marine corrosion is very great: over the years, people have conducted extensive research on the ecology, life history, seasonal distribution, activities and their symbiotic laws of Marine fouling organisms in order to subdue these harmful organisms: at present, there are many technologies related to Marine pollution and corrosion prevention, involving a wide range of areas and applications, including electrolytic antifouling technology Technique is an important anti-fouling and anti-corrosion technology. In offshore oil fields, electrolytic antifouling technology is currently mainly used in seawater treatment system, fire protection system and power system in the seawater cooling system, electric protection pipeline, the so-called electrolytic antifouling is through the electrochemical method, through the generated ions to expel and kill Marine life, the current commonly used electrolytic antifouling method are: electrolytic seawater chlorine method, electrolytic copper method, comprehensive method; The principle and characteristics of chlorine production from seawater are introduced in this paper, taking electrolysis antifouling of sea water pumps commonly used in oilfield offshore engineering as an example.

Electrolytic seawater chlorine process

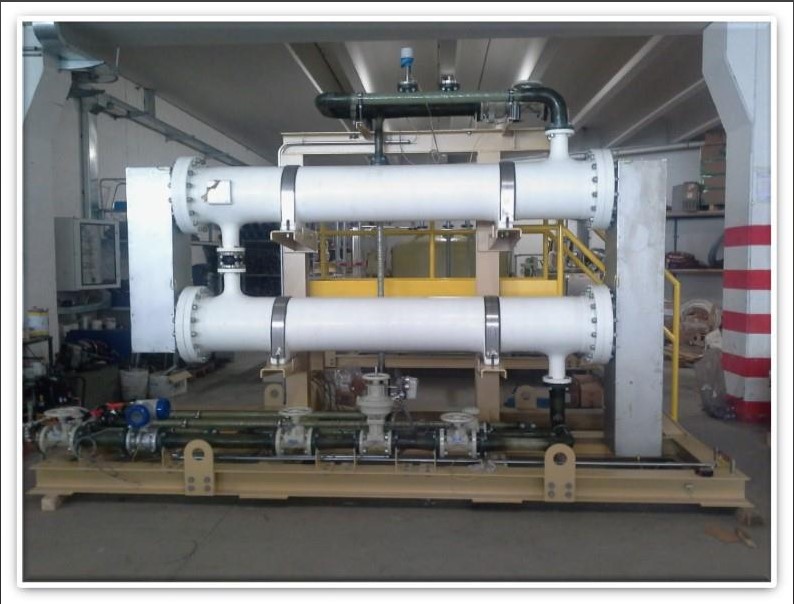

Electrolytic seawater chlorine making device is a device that prevents the attachment of Marine fouling organisms by electrolyzing water containing chlorine gas and sodium hypochlorite produced by seawater. Its principle is to introduce seawater into sodium hypochlorite generator through filter and flow control, and carry out electrolytic chemical reaction in the internal electrolytic cell. Chlorine gas and sodium hypochlorite are produced, and then the seawater containing chlorine gas and sodium hypochlorite is transported to the nozzle through the pipe, and the seawater containing the required amount of chlorine is inhaled through the sea pump, which can prevent the attachment, reproduction and growth of Marine organisms in the system to achieve the purpose of pollution prevention. The system is composed of electrolytic cell, rectifier, flowmeter, filter, stop valve, nozzle, etc. The electrolytic seawater chlorine making device is mainly used in seawater treatment system and seawater cooling system in offshore oil and gas engineering.

property

Electrolytic seawater chlorine method: its advantage is that the antifouling effect is better, and it can kill macrobody and microbody two kinds of Marine organisms. The disadvantages are that the device pipeline valve, complex equipment composition, large investment, high management requirements, the electrolytic cell in the device is easy to block and damage, and it needs to be cleaned and maintained frequently; The electrolyte is corrosive to the pipeline valve of the device and needs to be replaced frequently. After diluting the electrolyte into the production system, if the concentration is not well controlled, the system pipeline will also be corroded.

In summary, electrolytic antifouling technology is a simple and practical antifouling technology, which has a very broad application prospect in offshore oil and gas engineering construction. In the offshore oilfield, the generator cooling system of the offshore platform has used electrolytic anti-pollution technology. The system has been in operation for three years since 2021, and no blockage has been found. When we know about the users, they are satisfied with the use effect. In recent years, BLUEWAV sodium hypochlorite electrolytic seawater anti-fouling device has been used in the above systems of offshore platforms, and the effect is good. It is believed that with the development of offshore oil and gas engineering construction, the application field of electrolytic anti-fouling technology will be broader.

Bluewav Technology Co.,Ltd. in China & UAE

Whatsapp: +86 18610563976 | Website : https://www.bluewaVv.com

News

Electrolytic seawater is used in offsh oreoil and gas fields

2024-11-01 12:17:54